What Happens When you do not Service TPMS Sensors?

Many vehicle manufacturers as well as USTMA, state that the valve stem components are replaced every time the tire is serviced on vehicles with TPMS.

“Always remove and replace used snap-in valves when replacing tires. When new tires are installed, it is recommended to also replace all components that are included in the TPMS valve replacement kit.”

Source: U.S. Tire Manufacturers Association www.ustires.org/sites/default/files/USTMA_TISB_40.pdf

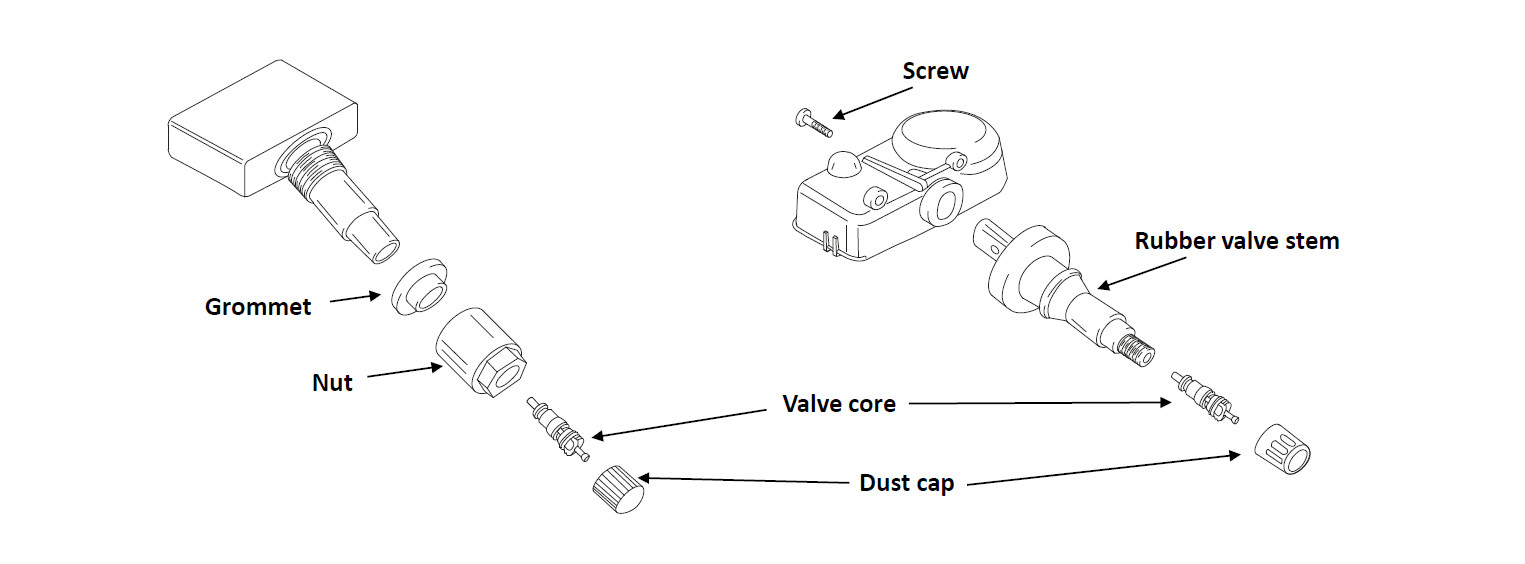

Typical Components Found in TPMS Repair Kits

Reasons For Proper Sensor Service and Repair

The OEM requires that the valve stem components are replaced every time the tire is serviced on vehicles with TPMS

| Clamp-in Kit Component | Replacement Reason | Result |

|---|---|---|

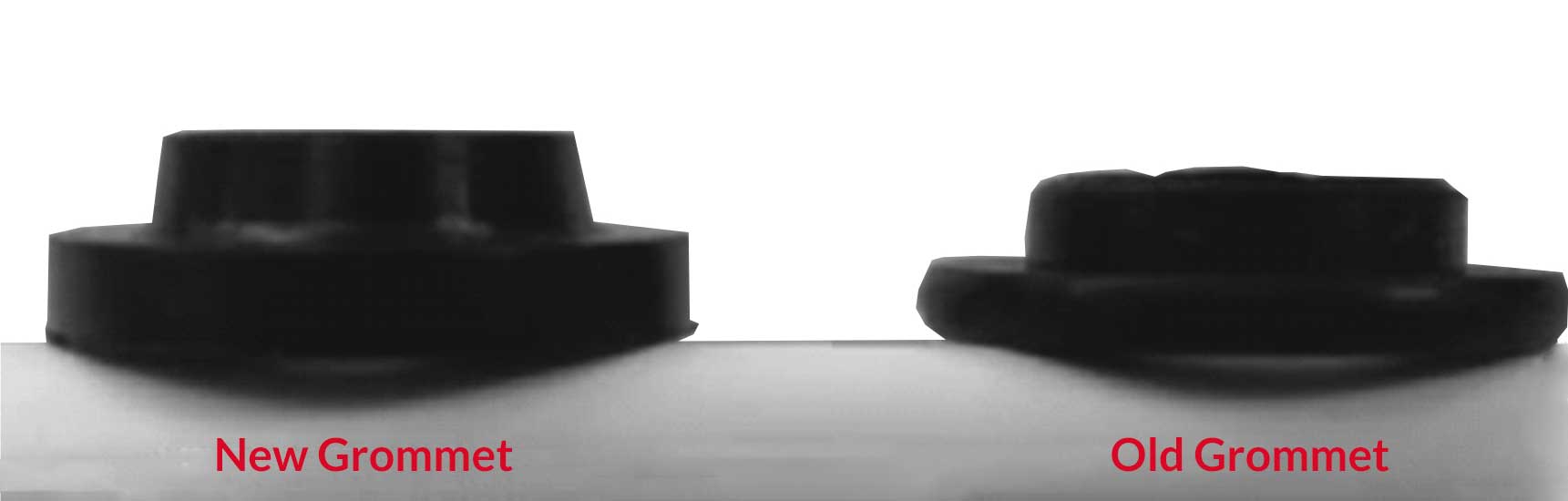

| (A) Grommet/Seal | Crack, deteriorate and leak over time | Leak path at valve stem |

| (B) Hex nut | Plating worn off, threads corrode | Leak path at valve stem |

| (C) Valve Core | Nickel plating strips leading to galvanic corrosion and seized valve cores | Leak at valve core, potential broken valve stem |

| (D) Valve cap w/seal | Valve cap seal wear | Allows moisture into core |

| (E) Metal Washer (some applications)(A) Grommet/Seal | Washer conforms to rim during installation | Leak path at valve stem |

| Snap-in Kit Component | Replacement Reason | Result | (F) Rubber TPMS snap-in valve | Crack, deteriorate and leak over time | Leak path at valve stem |

Refer to manufacturer’s specifications for proper torque requirements when replacing hex nuts and valve cores.

Bartec USA LLC

Bartec USA LLC