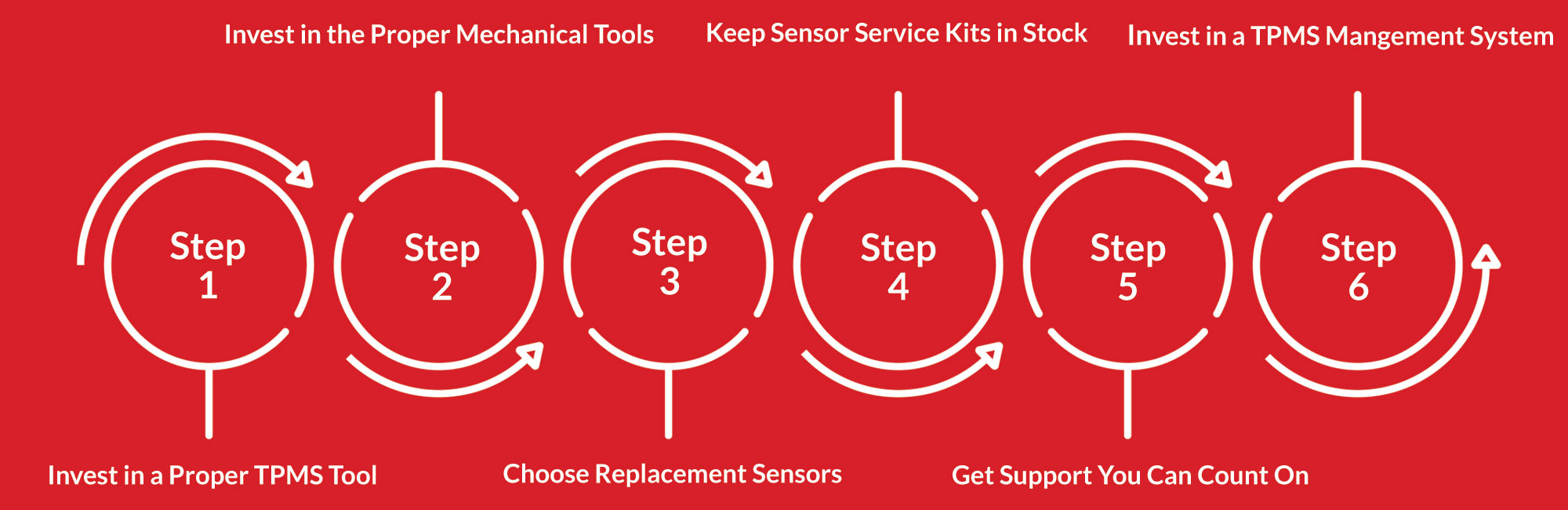

6 Steps to TPMS Success

Step 1 - Invest in a proper TPMS tool

A Combination Style Tool is key Not just any tool, but one that is capable of diagnostics and vehicle re-learning and clearing DTC’s. It is impossible to properly service TPMS and keep vehicles OPERATIVE without a combination style TPMS tool!

Step 2 - Invest in the Proper Mechanical Tools

A Complete Kit To properly remove and torque sensors and stems you need the right mechanical tools. Remember all TPMS Fasteners have a Torque Specification, therefore a properly calibrated tool is required for servicing!

Step 3 - Choose Replacement Sensors

There are many options for replacement. No matter the sensors you choose, make sure they are durable, reliable and are backed by robust testing and validation. Regardless of which sensors you decide on - YOU STILL NEED A COMBINATION STYLE TPMS TOOL!

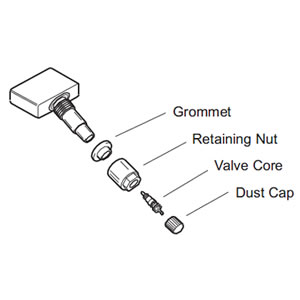

Step 4 - Keep Sensor Service Kits in Stock

Protect the sensor - change the parts! The seal, grommet, nut, valve core decay, wear and corrode and will eventually fail. EVERY time a tire is removed from a [TPMS] wheel, the sensor wear items should be replaced.

Step 5 - Get Support You Can Count On

Support is needed in the REAL world of TPMS Training for your technicians. Consumer info that helps you talk with your customers. Technical support for help during the tough situations. Choose partners that can help you get the most from your investment!

Bartec USA LLC

Bartec USA LLC